ABOUT

ABOUT

ABOUT

ABOUT

Our mission

Promoting the development of businesses and fostering innovation in the Quebec elastomers industry

Our vision

To be recognized as the reference in the rubber sector by being a driving force of excellence that positions businesses for a sustainable and prosperous future.

Our engagement

Implementing innovative and collaborative projects arising from common challenges to foster the growth of businesses and generate added value, all anchored in a sustainable development approach.

Our achievements

Our strategic axes

1. Sustainable development & circular economy

A reality common to all elastomer producing countries, the recycling problem remains and economically viable solutions are slow to be put in place. Despite some progress already made in Quebec, the niche must intensify its efforts and support our companies in implementing concrete solutions.

3. Supply and marketing

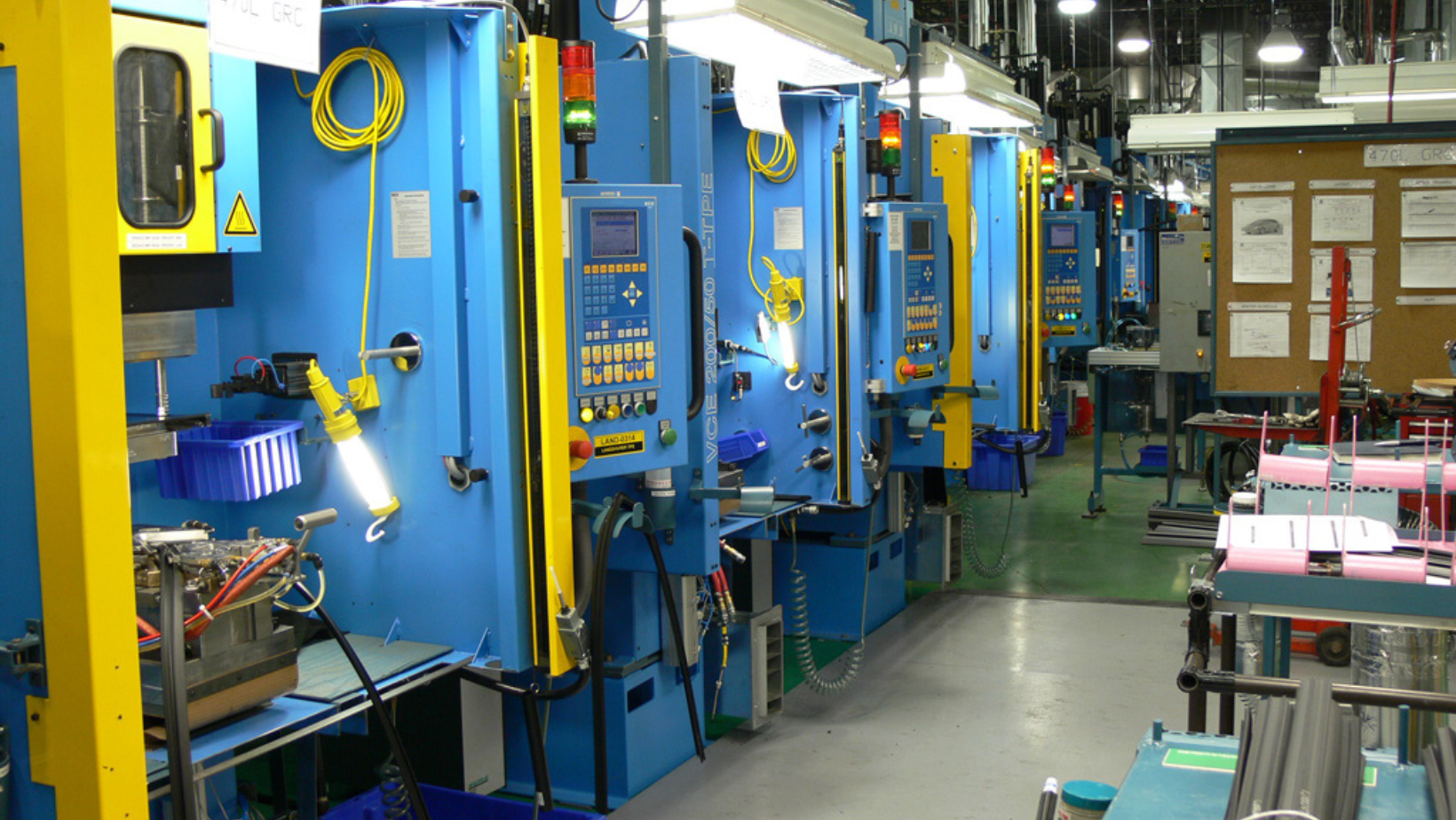

Already identified as an important issue for the sustainability of our businesses, with the demographic curve of employment in Quebec only accentuating this problem, our industry must ensure quality succession. The constant evolution of process technology, the complexity of new products, the increasingly demanding requirements of customers and the economic reality of the company raises the expectations of their employees.

2. Research and development

Innovation is a growth driver that will enable our Quebec businesses to stand out, particularly in terms of technological development to increase the added value of products, as well as sustainable innovation in the field of elastomers. The Quebec elastomers industry must find ways to renew itself. The development of an innovation ecosystem in elastomers through various strategic partnerships remains a crucial element not to be underestimated in the search for solutions. Our companies must coordinate and collaborate to create new value-added elastomer solutions to distinguish themselves globally.

4. Business Support

In the context of a labor shortage, companies in our sector often need to be accompanied or supported for various projects that they wish to put forward. This is why the Vallée des Élastomères is committed to supporting its member companies in their economic development needs. It also supports its companies in the implementation of new technologies and in the development of key technical personnel in collaboration with the sector committee (CSMO).

1. Sustainable development & circular economy

A reality common to all elastomer producing countries, the recycling problem remains and economically viable solutions are slow to be put in place. Despite some progress already made in Quebec, the niche must intensify its efforts and support our companies in implementing concrete solutions.

2. Research and development

Innovation is a growth driver that will enable our Quebec businesses to stand out, particularly in terms of technological development to increase the added value of products, as well as sustainable innovation in the field of elastomers. The Quebec elastomers industry must find ways to renew itself. The development of an innovation ecosystem in elastomers through various strategic partnerships remains a crucial element not to be underestimated in the search for solutions. Our companies must coordinate and collaborate to create new value-added elastomer solutions to distinguish themselves globally.

3. Supply and marketing

Already identified as an important issue for the sustainability of our businesses, with the demographic curve of employment in Quebec only accentuating this problem, our industry must ensure quality succession. The constant evolution of process technology, the complexity of new products, the increasingly demanding requirements of customers and the economic reality of the company raises the expectations of their employees.

4. Business Support

In the context of a labor shortage, companies in our sector often need to be accompanied or supported for various projects that they wish to put forward. This is why the Vallée des Élastomères is committed to supporting its member companies in their economic development needs. It also supports its companies in the implementation of new technologies and in the development of key technical personnel in collaboration with the sector committee (CSMO).